A lockstitch sewing machine’s essential for creating strong, secure seams by interlocking upper and lower threads. It’s widely used in both industrial and home settings due to its reliability and effectiveness across various fabrics. This machine’s mechanism involves the upper thread fed through a needle and a lower thread from a bobbin, forming a consistent stitch. You might be surprised at how many different types and applications exist, especially in garment construction. There’s much more to explore! In addition to the traditional lockstitch, there are variations like the low shank sewing machine explained, which offers versatility in foot attachments and can handle a range of sewing tasks. These machines are particularly favored by home sewists for their adaptability and ease of use. Whether you’re quilting, sewing garments, or creating crafts, understanding the nuances of different sewing machine types can enhance your sewing experience and outcomes.

Key Takeaways

- A lockstitch sewing machine creates strong seams by interlocking upper and lower threads, suitable for various fabric types.

- The Type 301 lockstitch is known for its reliability and versatility in garment manufacturing.

- Lockstitch machines produce consistent stitches that appear the same on both sides, enhancing seam appearance.

- These machines are efficient for low-volume production and can sew around 90° at the needle.

- Regular maintenance, such as cleaning and lubricating, is essential to prevent common issues like uneven stitches.

Overview of Lockstitch Sewing Machines

Lockstitch sewing machines are essential tools in both industrial and home sewing settings, as they create strong, secure seams by interlocking an upper needle thread with a lower bobbin thread.

The most common type, the Type 301, is favored in garment manufacturing for its reliability and versatility. These machines produce consistent stitches that look the same on both sides of the fabric, making them ideal for various applications.

Lockstitch machines excel at sewing straight seams, which are vital for garment construction, and can also create zigzag stitches. Their strength and resistance to unraveling allow you to work with all types of fabrics, from lightweight to heavy materials.

Advanced features in industrial sewing machines enhance efficiency and productivity, making lockstitch a top choice.

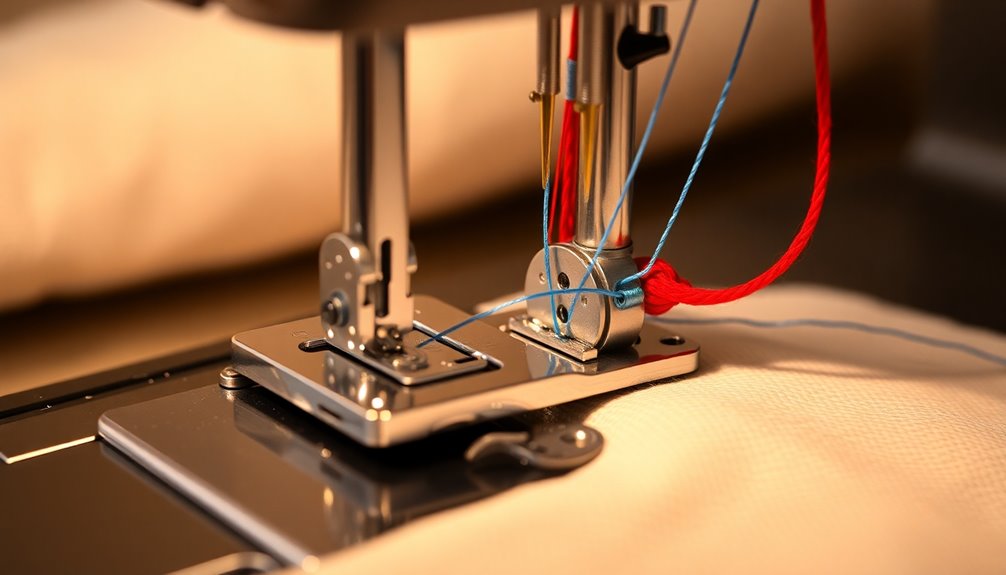

Mechanism of Lockstitch Formation

In a lockstitch sewing machine, the mechanism that forms the stitch relies on the precise interaction between the upper and lower threads. The upper thread, fed from a spool through a tension mechanism and needle, works with the lower thread, which is wound on a bobbin.

As you lower the needle through the fabric, a rotating hook catches the upper thread, creating a loop around the lower thread. This interlocking forms a strong lockstitch.

Proper thread tension is essential, as it guarantees the stitches sit in the center of the material thickness, providing a secure seam.

Characteristics of Lockstitches

Stitches created by the lockstitch mechanism are notable for their strength and uniformity, making them a favorite among sewists.

These stitches form by interlocking the needle thread with the bobbin thread, creating a secure seam that looks identical on both sides of the fabric. The Class 300 lockstitch, often called the double lockstitch, is especially resilient and prevents unraveling, even if one stitch breaks.

You'll find lockstitches can stretch up to 30%, making them perfect for comfort and stretch garments.

Whether you're using a Type 301 for basic seams or a Type 306 for blind stitching, the industrial lockstitch is essential for achieving a clean, professional finish in your sewing projects.

Types of Lockstitches

While exploring the world of sewing, you'll discover various types of lockstitches, each designed for specific applications. Understanding these lock stitches can enhance your sewing projects and improve efficiency with lockstitch machines.

Here are some key types to take into account:

- Type 301: The simplest lockstitch for secure seams across various fabrics.

- Type 304: A zig-zag lockstitch, perfect for attaching trimmings without neatening edges.

- Type 306: A blind stitch variant, providing a secure option for less-visible hems.

- Types 308 and 315: These produce longer and wider zig-zag stitches, ideal for seaming and cover stitching.

These variations in Types of Industrial Sewing allow you to tailor your approach based on fabric type and desired stretch, enhancing versatility in your projects.

Applications of Lockstitches in Garment Construction

When it comes to garment construction, lockstitches play an essential role in both seaming techniques and decorative stitching applications.

You'll find them securing seams on various fabrics while also enhancing the visual appeal of details like collars and hems.

Their versatility makes them a go-to choice for achieving both strength and aesthetic in your sewing projects.

Garment Seaming Techniques

Lockstitch sewing machines play a crucial role in garment construction, as they provide a strong and visually appealing seam that looks identical on both sides of the fabric.

When you're working on garment seaming techniques, the needle lockstitch is your go-to for various applications. Here are some key uses:

- Top-stitching collars and cuffs for a polished look

- Joining pockets and sleeves with reliable strength

- Run stitching for a neat finish on seams

- Attaching trimmings like lace and elastic without fraying

These features make lockstitch machines indispensable in industrial sewing.

Their ability to pivot at 90° while maintaining quality guarantees you can tackle intricate designs with ease.

Decorative Stitching Applications

As you explore decorative stitching applications in garment construction, you'll discover how versatile lockstitches can enhance your projects.

These lock stitches are perfect for decorative top-stitching on collars, cuffs, and hems, adding visual appeal while guaranteeing a clean finish on both fabric sides.

With lockstitches, you can create intricate designs and securely attach embellishments like lace, piping, and other trimmings without compromising seam quality.

They also produce various decorative stitch types, such as blind and stretch stitches, essential for stretchy and delicate fabrics.

Their consistent appearance on both sides makes them ideal for reversible garments.

Plus, the strength of lockstitches guarantees durability, making them great for sportswear and activewear, where seams need to withstand stress and movement.

Advantages of Using Lockstitch Machines

While many sewing machines offer various functions, the advantages of using lockstitch machines stand out, especially for those focused on seam quality and durability.

When you choose a lockstitch machine, you'll enjoy several key benefits:

- Consistent Appearance: Stitches look the same on both sides, ideal for projects needing thread color matching.

- Durable Seams: A break in one stitch won't unravel the entire seam, enhancing garment longevity.

- Smooth Finish: Less prone to puckering, lockstitch machines provide a cleaner look on fabric.

- Efficiency: Perfect for low-volume production, they sew around 90° at the needle point, making them a staple in industrial and domestic applications.

With these features, lockstitch machines truly elevate your sewing experience.

Comparison With Other Sewing Machine Types

When comparing lockstitch machines to other types, you'll notice distinct differences in functionality and use.

Overlock machines excel at edge finishing, while chainstitch machines focus on decorative stitching.

Flatlock machines are great for stretchy fabrics, but lockstitch machines stand out for their strength and versatility in garment construction.

Lockstitch vs. Overlock Machines

Understanding the differences between lockstitch and overlock machines is essential for anyone delving into sewing, especially in garment construction.

Here's a quick comparison:

- Lockstitch Machines: Use two threads (needle and bobbin) for a neat, consistent stitch on both fabric sides.

- Overlock Machines: Utilize three to four threads to create overlock stitches that also trim edges, preventing fraying.

- Ideal Use: Lockstitch is perfect for various fabrics, while overlock excels with stretchy materials.

- Applications: Lockstitch is mainly for seaming, whereas overlock machines finish raw edges and add decorative stitches.

Lockstitch vs. Chainstitch Machines

After exploring the differences between lockstitch and overlock machines, it's clear that lockstitch machines also stand apart from chainstitch machines in notable ways.

Lockstitch machines create stitches by interlocking an upper needle thread with a lower bobbin thread, resulting in a secure seam that looks the same on both sides. In contrast, chainstitch machines use one or two threads to form looped patterns, making them ideal for decorative stitching and hems but less reliable for seam integrity.

While lockstitch is perfect for various fabric weights in garment construction, chainstitch is better suited for stretchy materials. Additionally, lockstitch machines require precise tension management, whereas chainstitch machines are more forgiving but can unravel easily if not secured properly.

Lockstitch vs. Flatlock Machines

While both lockstitch and flatlock machines are essential tools in garment construction, they serve distinct purposes and produce different seam types.

Here's a quick comparison:

- Lockstitch: Uses a single needle and bobbin thread, creating secure seams ideal for various fabrics.

- Flatlock: Joins fabric layers without overlap, perfect for lightweight and stretchy fabrics like swimwear.

- Seam Type: Lockstitch offers identical stitching on both sides, while flatlock provides decorative exposed seams.

- Application: Lockstitch is great for top-stitching and seaming, whereas flatlock excels in finishing seams in athletic wear.

Ultimately, choosing between lockstitch and flatlock machines depends on the type of fabrics and seams you need for your projects.

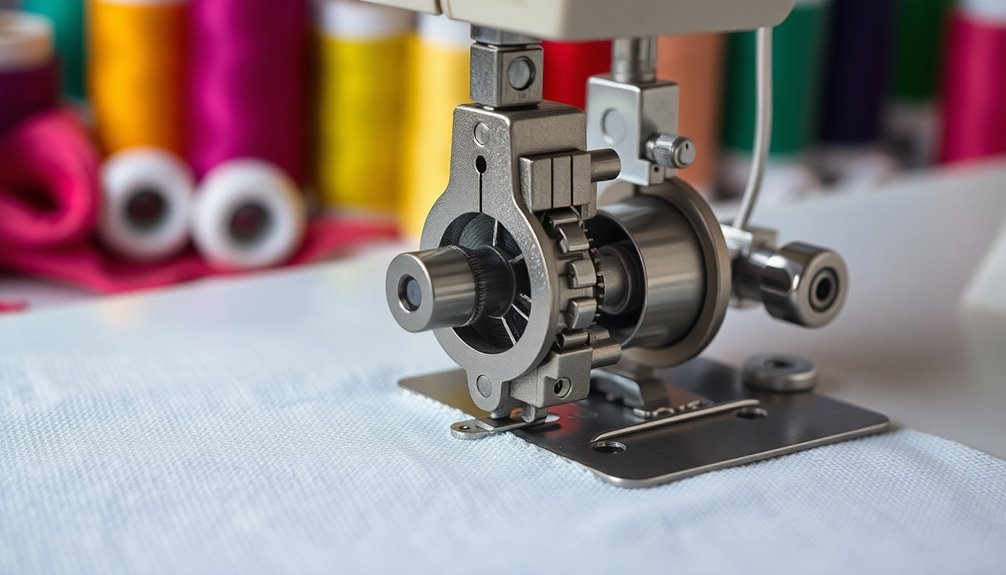

Maintenance Tips for Lockstitch Machines

To keep your lockstitch sewing machine running smoothly, regular maintenance is essential. Follow these maintenance tips to guarantee peak performance:

| Task | Frequency | Importance |

|---|---|---|

| Clean feed dogs | After each project | Prevents lint buildup |

| Lubricate moving parts | Every 8 hours of use | Reduces wear and tear |

| Adjust thread tension | Periodically | Guarantees consistent stitching |

| Replace sewing needle | Every 8-10 hours | Maintains fabric integrity |

| Inspect bobbin case | Before each use | Avoids uneven stitches |

Common Issues and Troubleshooting

Lockstitch sewing machines can encounter several common issues that may disrupt your sewing projects. Identifying and troubleshooting these problems early can save you time and frustration.

Here are some typical challenges you might face:

- Thread tension problems can lead to uneven stitches or thread breakage.

- A jammed bobbin case often causes skipped stitches or thread tangling.

- Improper needle installation or a dull/bent needle can also result in skipped stitches.

- Regular maintenance, including cleaning and oiling your machine, is essential to prevent these issues.

Future Trends in Lockstitch Technology

Troubleshooting common issues with lockstitch machines is just the beginning of understanding this technology's evolution. Future trends indicate significant advancements in lockstitch technology. You'll see automation leading to fully automated machines that handle multi-step processes, cutting down on labor costs and time. Innovations in eco-friendly threads will enhance seam durability while reducing environmental impact. Additionally, the focus on ergonomic designs will improve operator comfort, decreasing fatigue during long hours. Digital connectivity will also play an essential role, allowing real-time monitoring and predictive maintenance.

| Trend | Description | Benefits |

|---|---|---|

| Automation | Fully automated lockstitch machines | Reduced labor costs |

| Eco-friendly materials | Development of sustainable threads | Lower environmental impact |

| Ergonomic designs | Improved machine comfort | Enhanced productivity |

| AI integration | Adaptive tension control | Better stitch quality |

| Digital connectivity | Real-time monitoring | Optimized performance |

Frequently Asked Questions

What Is a Lockstitch Sewing Machine Used For?

A lockstitch sewing machine's used for various seaming operations, ensuring strong and secure stitches that look identical on both sides of the fabric.

You can use it for tasks like top-stitching collars and cuffs, creating a clean finish on sheer materials.

It excels in producing decorative elements and attaching embellishments, making your garment construction versatile.

Plus, it enhances seam reliability, especially in low-volume production, reducing the risk of unraveling.

What Is the Difference Between Lockstitch and Straight Stitch?

Did you know that around 90% of sewing projects use a lockstitch for its durability?

The main difference between lockstitch and straight stitch lies in how they're formed. A lockstitch interlocks an upper needle thread with a lower bobbin thread, creating a secure seam that looks the same on both sides.

In contrast, a straight stitch consists of a single thread running in a straight line, which may lack the same strength without reinforcement.

What Are the Disadvantages of Lockstitch?

When considering the disadvantages of lockstitch, you might find that it struggles with stretchy fabrics, leading to potential seam breaks.

If you don't manage thread tension properly, puckering can occur, making your project look unprofessional.

These machines also require regular maintenance, which can be time-consuming and cause delays.

Plus, if you're a beginner, the threading complexity and alignment needs can be quite challenging, limiting your sewing experience.

Do We Still Use the Lockstitch Sewing Machine?

Did you know that around 50% of sewing machines used in garment factories are lockstitch machines? Yes, they're still widely used today!

You'll find them essential for creating strong, consistent seams that look great on both sides. Whether you're sewing at home or in a factory, these machines handle seaming, top-stitching, and attaching trims effectively.

Their durability and versatility keep them relevant in modern garment production, making them a staple in the industry.

Conclusion

In the world of sewing, a lockstitch machine is your steady anchor, weaving together fabric and creativity into a seamless tapestry. As you navigate through threads of innovation and tradition, remember that each stitch tells a story. By embracing the rhythm of this versatile tool, you're not just constructing garments; you're crafting your unique narrative. Keep it well-maintained and watch as your creations flourish, transforming mere fabric into a canvas of self-expression.