A sewing machine converts mechanical motion into precise stitches to join fabric layers. When you press the pedal or turn the handwheel, it moves the needle up and down, piercing the fabric. The machine controls thread tension and guides the bobbin thread to create interlocking stitches. Proper maintenance and understanding the interaction of components, like the bobbin and tension system, guarantee smooth stitching. Continuing explores the inner workings that make sewing machines operate so efficiently.

Key Takeaways

- The sewing machine converts mechanical motion into stitches by coordinating the needle, thread tension, and bobbin mechanism.

- The upper thread and bobbin thread interlock to form a secure lockstitch during needle movement.

- Thread tension controls stitch tightness, ensuring even stitches and preventing puckering or loose seams.

- The bobbin holds the lower thread and works within the bobbin case, guiding it smoothly for consistent stitching.

- Regular maintenance and proper adjustments of tension and threading are essential for optimal machine operation.

A sewing machine works by transforming mechanical motion into precise stitching that joins fabric together. When you press the pedal or turn the handwheel, the machine’s motor or hand crank activates, causing a series of interconnected parts to move in harmony. At the heart of this process is the needle, which moves up and down rapidly, piercing the fabric to create stitches. But to produce even, secure stitches, the machine relies heavily on the coordination between the thread tension and the bobbin mechanism.

The thread tension is essential because it controls how tightly the upper thread pulls against the fabric and the bobbin thread. If the tension is too tight, your stitches might pucker or break; if too loose, the stitches could be loose or uneven. Adjusting the tension involves turning a small dial or knob on the machine, which increases or decreases the pressure on the upper thread. This guarantees that both threads—upper and bobbin—interact smoothly, forming a balanced stitch. Proper thread tension is fundamental for a professional-looking seam and prevents issues like skipped stitches or thread bunching.

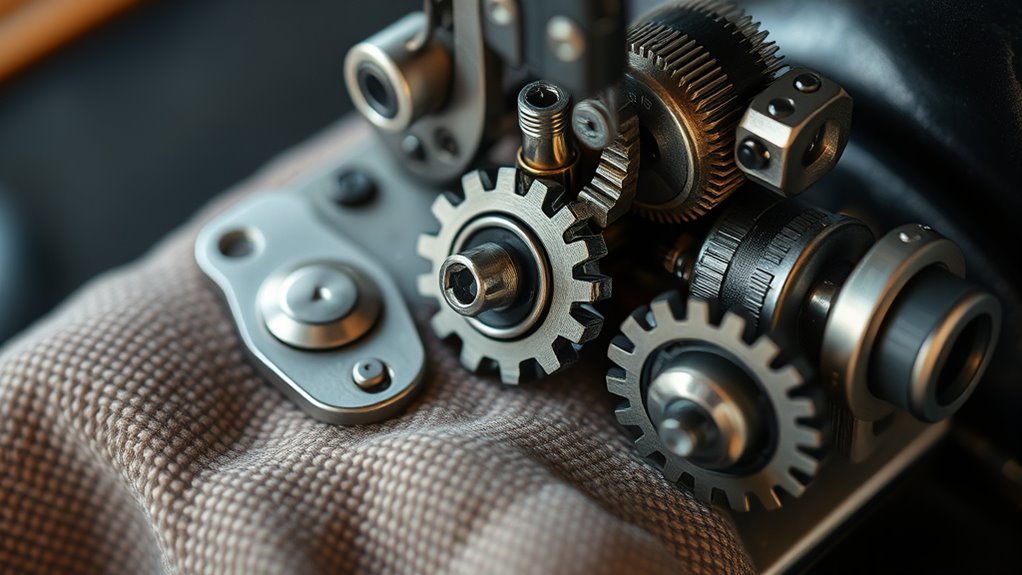

Beneath the needle plate, the bobbin mechanism plays a critical role in completing each stitch. The bobbin is a small spool that holds the lower thread, which interlocks with the upper thread created by the needle. When you start sewing, the machine’s bobbin case guides the bobbin thread upward through a small opening called the tension spring or bobbin tension. This tension is carefully calibrated to guarantee the bobbin thread pulls smoothly without slipping or bunching. As the needle moves down, it catches the bobbin thread through a loop, then pulls it up as the needle rises, creating a lockstitch. This intricate process depends on the precise operation of the bobbin mechanism, which must work seamlessly with the upper thread tension to produce even stitches. Proper maintenance of the bobbin case ensures consistent tension and smooth sewing performance.

The bobbin case also helps to regulate the tension of the lower thread, preventing it from becoming too loose or too tight. When the tension is just right, the stitches sit flat and secure, with no puckering or loose loops. If you notice uneven stitches or thread bunching, adjusting the bobbin tension or rethreading the machine can often fix the problem. Maintaining the bobbin mechanism, cleaning out lint, and ensuring the tension is set correctly are essential steps to keep your sewing machine running smoothly.

In essence, the harmony between thread tension and the bobbin mechanism ensures your sewing machine produces consistent, neat stitches. By understanding how these components work together, you can troubleshoot common issues and achieve professional results every time you sew.

Frequently Asked Questions

How Do Different Fabric Types Affect Sewing Machine Operation?

Different fabric types impact your sewing machine’s operation, especially with fabric stretch and sewing precision. Stretchy fabrics like jersey require adjusting your tension and using a stretch stitch to prevent puckering or skipped stitches. Denser fabrics like denim need a stronger needle and slower sewing speed. By understanding these differences, you can fine-tune your machine settings for smooth stitching, ensuring your project looks professional regardless of fabric type.

Can Sewing Machines Be Adjusted for Different Stitch Lengths Automatically?

Of course, your sewing machine can automatically adjust stitch lengths with some fancy sensor-based sewing technology. It’s like having a personal tailor who knows just how tight or loose your stitches should be, no manual fuss needed. These machines detect fabric thickness and adapt stitch length seamlessly. So, you can sit back, relax, and let your sewing machine do the thinking—making your sewing projects smoother and more efficient.

What Maintenance Is Necessary to Keep a Sewing Machine Running Smoothly?

To keep your sewing machine running smoothly, regularly lubricate the needle area to prevent rust and guarantee smooth stitching. Check and adjust the tension to maintain proper stitch quality. Clean lint and dust from the bobbin case and feed dogs, and oil moving parts as recommended by your machine’s manual. Proper maintenance extends the life of your machine and ensures consistent, high-quality stitches every time you sew.

How Do Computerized Sewing Machines Differ From Manual Ones?

Computerized sewing machines differ from manual ones by offering advanced features like embroidery options and automatic stitch settings. They often include touchscreens for easy programming and customization. You can control speed and functions with foot pedal controls, making sewing more efficient. Unlike manual machines, they take care of complex stitches automatically, letting you focus on creativity. This makes your sewing projects quicker, more precise, and packed with professional-looking details.

Are There Sewing Machine Models Specifically Designed for Quilting?

You’ll find that some sewing machine models are thoughtfully designed with quilt-specific features, making quilting more enjoyable. These quilting machine types often include larger workspaces, specialized stitches, and adjustable speeds to handle thick layers gracefully. Choosing a dedicated quilting machine means you get smooth, precise stitching, whether you’re working on a small project or a large quilt. These features help you achieve beautiful results with less frustration, elevating your quilting experience.

Conclusion

Now that you understand how a sewing machine’s inner magic works, you hold the key to transforming threads into beautiful creations. Think of it as a tiny orchestra, each part playing its role in perfect harmony. With this knowledge, you’re not just stitching fabric—you’re weaving stories, dreams, and memories. So, pick up your machine, let your imagination run wild, and turn simple threads into masterpieces that whisper your unique story.