To fix your sewing machine handwheel, start by checking for thread jams and obstructions in the bobbin area. Next, apply high-quality lubrication to the handwheel and its moving parts. Inspect the handwheel mechanism for dirt or damage, then verify the clutch motor is properly adjusted. Confirm the bobbin size and make sure it's inserted correctly. If you're still having trouble, professional assistance might be the answer—and there's more to learn about keeping your machine in top shape!

Key Takeaways

- Inspect the bobbin area and upper thread path for any tangled threads or obstructions that may hinder movement.

- Apply high-quality sewing machine oil to the handwheel's axle and moving parts to reduce friction and ensure smooth operation.

- Remove the handwheel to check for dirt or debris and verify proper alignment to facilitate easy turning.

- Ensure the clutch motor is correctly adjusted according to the user manual to prevent mechanical resistance affecting the handwheel.

- Confirm the bobbin is the correct size and properly inserted to avoid complications during sewing that could affect handwheel functionality.

Check for Thread Jams and Obstructions

One of the first things you should do when fixing your sewing machine's handwheel is to check for thread jams and obstructions.

Start by inspecting the bobbin area and upper thread path for any tangled or caught threads that might hinder the handwheel's movement. Remove the needle plate and bobbin case to clean any debris or fabric that could be blocking the handwheel.

Verify your threading is correct; improper threading can lead to tension issues and thread jams. Manually rotate the handwheel counterclockwise to dislodge any potential jams, and see if it moves more freely afterward.

Regularly cleaning the hook area helps prevent lint and dust build-up, which can lead to further thread jams and stiffness in the handwheel.

Apply Lubrication to the Handwheel

To keep your sewing machine's handwheel operating smoothly, applying lubrication is vital.

First, turn off and unplug your sewing machine for safety during maintenance. Use high-quality sewing machine oil specifically designed for mechanical parts.

Apply a few drops of oil to the handwheel's axle and any moving parts to reduce friction, ensuring easy movement. This routine maintenance is essential for prolonging your machine's lifespan and promoting smooth operation.

After applying oil, wipe away any excess with a clean cloth to prevent dirt accumulation, which can lead to further issues.

Regularly lubricating the handwheel will help maintain efficiency and keep your sewing machine in excellent condition, ready for your next project.

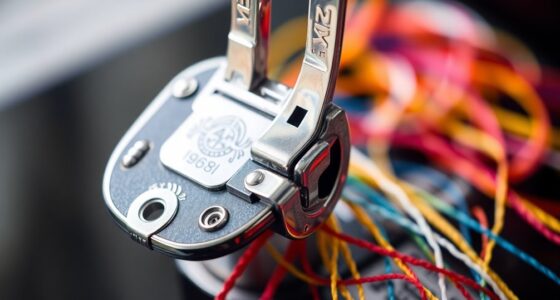

Inspect the Handwheel Mechanism

Inspecting the handwheel mechanism is essential for guaranteeing your sewing machine operates smoothly.

Start by removing the handwheel to check for any dirt or debris that may obstruct its movement. Next, look for signs of wear or damage that could affect functionality. Finally, verify proper alignment to avoid difficulty in turning.

Follow these steps:

- Clear any dirt or debris from the handwheel area.

- Check for wear or damage in the handwheel assembly.

- Tighten loose components to prevent the handwheel from sticking.

Ensure Proper Clutch Motor Adjustment

After ensuring the handwheel mechanism is clean and properly aligned, it's important to address the clutch motor adjustment.

The clutch motor controls the engagement and disengagement of the needle mechanism, directly influencing how smoothly the handwheel operates. Check your user manual for the specific adjustments related to your sewing machine model.

Misalignment or incorrect settings can create mechanical resistance, making it difficult to turn the handwheel during operation. Regular inspection is essential, as wear and tear can affect performance.

If you're unsure about making these adjustments, don't hesitate to seek professional help to avoid potential damage to your machine.

Proper clutch motor adjustment is vital for ideal sewing performance and functionality.

Verify Bobbin Size and Insertion

To keep your sewing machine running smoothly, you need to verify that your bobbin is the correct size for your model.

Make sure it's properly inserted and clicks into place, as this is essential for preventing thread jams and other issues.

If you're unsure about compatibility, check the original bobbin or consult your user manual.

Check Bobbin Compatibility

Verifying your bobbin is the right size for your sewing machine can prevent jams and operational issues down the line. A bobbin that doesn’t fit properly can lead to uneven stitching, thread tension problems, and ultimately, sewing machine jams. To avoid these complications, always check the manufacturer’s specifications for the correct bobbin size. If you do find yourself facing issues despite using the correct bobbin, there are several sewing machine jamming solutions available that can help you troubleshoot and resolve the problem efficiently.

Here's how to check bobbin compatibility effectively:

- Compare Sizes: Look at your bobbin and compare it with the original or recommended size for your sewing machine. This verifies you have the correct size.

- Inspect Condition: Regularly check your bobbin for wear or damage, as this can disrupt sewing and lead to thread tangling.

- Consult Manual: Always refer to your sewing machine's user manual for specific guidelines on bobbin compatibility and insertion techniques tailored to your model.

Proper Bobbin Insertion

Once you've confirmed that your bobbin is the right size for your sewing machine, it's time to focus on proper bobbin insertion.

Start by placing the bobbin in the bobbin case with the thread unwinding counterclockwise, ensuring it's compatible with your machine. After inserting, check that the bobbin case is securely seated to prevent misalignment while sewing.

Regularly inspect your bobbin for wear, cracks, or warping to maintain efficient operation. If you notice issues with thread tension or experience thread jams, re-evaluate your bobbin insertion. You might need to re-thread the machine to resolve these problems.

Seek Professional Assistance if Needed

If you've tried troubleshooting your sewing machine handwheel and the problem still isn't resolved, it might be time to call in the experts.

You can use the manufacturer's service center locator to find a certified technician near you.

Be ready to explain the symptoms you've noticed and any changes in performance, as this information can help them diagnose the issue more efficiently.

When to Call Experts

How can you tell when it's time to call in the experts for your sewing machine's handwheel issues? If you've tried troubleshooting but your hand wheel still isn't turning, it's vital to seek professional assistance.

Here are key signs to watch for:

- Persistent Issues: If the handwheel remains stuck despite your efforts, it may indicate deeper mechanical issues.

- Unusual Noises: Any strange sounds while attempting to turn the handwheel signal potential problems.

- Failed Repairs: If the same issue keeps recurring, it's time to consult a certified technician.

Documenting your troubleshooting steps will help professionals understand the problem better.

Don't forget that many sewing machine brands offer customer support, which can guide you before you resort to repairs.

Regular maintenance is essential for peak performance.

Finding Authorized Service Centers

When you've determined that your sewing machine's handwheel issues need professional attention, finding the right authorized service center is the next step. You can use the service center locator on your sewing machine brand's official website, like Brother, for accurate results. If troubleshooting hasn't helped, don't hesitate to contact a certified technician for specialized repair expertise.

Here's a quick reference to assist you:

| Action | Resources |

|---|---|

| Locate Service Center | Brand's service center locator |

| Contact Technician | Customer support lines |

| Keep Repair Records | Maintenance history |

| Schedule Regular Maintenance | Authorized service centers |

Regular maintenance can prolong your sewing machine's lifespan, ensuring peak performance and fewer future problems.

Frequently Asked Questions

How to Fix a Sewing Machine Handwheel?

If your sewing machine handwheel isn't moving, first, unplug the machine and check for thread jams or fabric stuck in the bobbin area.

Remove the needle plate and bobbin case to clear any lint or tangled threads. Make sure the bobbin's properly sized and inserted.

If it's still stuck, inspect the alignment of the bobbin case and look for any broken needle pieces.

If the problem continues, consult the manual or seek professional help.

Why Is My Hand Wheel Not Moving the Needle?

If your handwheel's not moving the needle, it's like trying to turn a key in a rusty lock.

First, check for a thread jam in the bobbin area that might be causing the problem.

Make certain the presser foot's lowered, and the bobbin case is aligned properly with the correct size.

Also, inspect the handwheel's clutch mechanism and verify it's engaged.

Regular cleaning and lubrication can keep everything running smoothly too.

What Happens if You Turn the Handwheel the Wrong Way?

If you turn the handwheel the wrong way, you'll likely face thread jams and tangled threads, disrupting your sewing.

You might end up with a "bird's nest" of thread under your fabric, complicating your project.

Forcing the handwheel in the wrong direction can damage the machine's hook mechanism, leading to costly repairs.

To keep everything running smoothly, always turn the handwheel counterclockwise and avoid unnecessary complications in your sewing process.

What to Do When Your Sewing Machine Locks Up?

When your sewing machine locks up, it can feel frustrating, like a car engine sputtering unexpectedly.

First, turn off and unplug your machine for safety. Check for thread jams or fabric caught around the bobbin area.

Remove the needle plate and bobbin case to clean out debris. Make sure the presser foot's lowered and the bobbin case is aligned.

If it's still stuck, you might want to call a professional for help.

Conclusion

With a little patience and some elbow grease, you can tackle that stubborn handwheel like a sewing superhero. Just imagine your sewing machine as a rebellious teenager, throwing a fit over a thread jam or a misplaced bobbin. By following these steps, you'll have it spinning smoothly again in no time. If all else fails, just remember: even superheroes sometimes need a sidekick—so don't hesitate to call in a professional for backup!