To keep your sewing machine running smoothly, regularly clean out lint and dust from the bobbin case and under the needle plate using a soft brush or cloth. Oil the moving parts as recommended in your manual, but avoid over-oiling. Check thread tension and re-adjust if needed for even stitches. Proper maintenance prevents issues like thread jams and skipped stitches. Keep your machine well-maintained, and discover more tips to make certain of consistent, professional results.

Key Takeaways

- Regularly clean lint, dust, and thread from the bobbin case and machine interior to prevent jams and maintain smooth operation.

- Oil moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Check and adjust thread tension for balanced stitches, testing on scrap fabric before sewing your project.

- Remove and clean the bobbin case carefully, ensuring it snaps securely back into place for optimal tension.

- Perform routine maintenance, including cleaning and oiling, to extend your sewing machine’s lifespan and ensure consistent stitch quality.

Maintaining your sewing machine is essential to guarantee it runs smoothly and lasts for years. One of the most important aspects of proper maintenance is ensuring the thread tension is correctly set. When your thread tension is off, your stitches can become loose, tight, or uneven, which affects the overall quality of your sewing. To keep it in check, regularly check the tension dial and make small adjustments as needed. If your stitches are not forming properly, it could be a sign that the tension is too tight or too loose. Always test on scrap fabric before sewing your main project to avoid wasting material. Proper tension ensures the thread from the top and bottom of your fabric interlocks seamlessly, resulting in balanced stitches and a professional finish. Regularly inspecting and adjusting your sewing machine’s tension can help prevent issues like thread breakage or uneven stitches, saving you time and frustration.

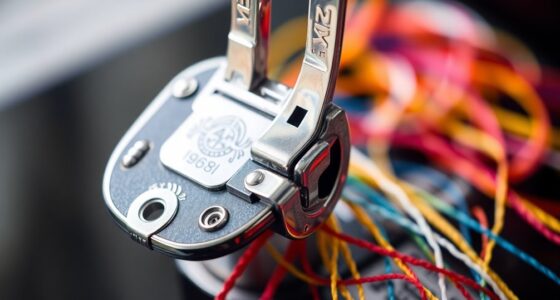

Another critical component that directly impacts your sewing machine’s performance is the bobbin case. The bobbin case holds the bobbin in place and helps maintain consistent stitch quality. Over time, lint, dust, and thread fragments can accumulate in and around the bobbin case, causing it to function improperly. Regularly remove the bobbin case and clean it thoroughly with a small brush or a soft cloth. Be cautious not to damage the delicate latch or the tension spring inside. Keeping your bobbin case clean and free of debris ensures smooth bobbin winding and prevents issues like thread jams or skipped stitches. When re-inserting the bobbin case, make sure it snaps into place securely and that the bobbin spins freely. Proper placement and maintenance of the bobbin case are vital for consistent tension and stitch quality. Additionally, understanding the importance of proper maintenance can extend your machine’s lifespan and improve your sewing results.

Frequently Asked Questions

How Often Should I Replace My Sewing Machine Needle?

You should replace your sewing machine needle after every 8 to 12 hours of sewing or with each project to guarantee peak needle quality. Regular needle replacement boosts sewing machine longevity by preventing skipped stitches, fabric damage, and machine jams. Keep an eye on bent or dull needles, and swap them out promptly. Doing so maintains smooth operation and helps your machine perform at its best for years to come.

Can I Use Household Oil on My Sewing Machine?

Using household oil on your sewing machine is a big no-no; it’s like putting ketchup on a gourmet meal! Household oil isn’t designed for machine lubrication, which can cause gunk buildup or damage. Always use the recommended sewing machine oil for proper lubrication. This guarantees smooth operation and prolongs your machine’s life, saving you from costly repairs and frustrating jams. Stick to proper oil for the best results!

What Signs Indicate My Machine Needs Professional Servicing?

You should seek professional servicing if your machine struggles with proper calibration or if the bobbin tension feels inconsistent. Signs include uneven stitches, thread jams, or skipped stitches, which indicate internal issues. If adjusting tension or calibration doesn’t fix these problems, a technician can diagnose and repair the underlying causes. Regular servicing guarantees your machine stays in top condition, preventing more extensive damage down the line.

Is It Safe to Sew After Cleaning and Oiling?

Yes, it’s safe to sew after cleaning and oiling your machine, but you should follow safety precautions. Make sure the machine is unplugged during cleaning and oiling to prevent accidents. Wait a few minutes after oiling to let it absorb, and wipe away excess oil. Regular cleaning frequency keeps your machine running smoothly, reducing the need for repairs. Always check your manual for specific safety instructions to guarantee safe sewing.

How Do I Troubleshoot Thread Jams Effectively?

Troubleshoot thread jams by tackling tension troubles and bobbin blunders. First, check the thread tension to make sure it’s neither too tight nor too loose. Next, examine and align the bobbin properly, making sure it’s seated correctly and spinning smoothly. Clear any tangled threads or lint, and rethread the machine carefully. Consistent checking and correct threading prevent future jams, keeping your sewing smooth and stress-free.

Conclusion

Think of your sewing machine as a trusted friend—regular cleaning and oiling keep it running smoothly, just like tending to a relationship. When I neglected mine, it started jamming during a vital project, teaching me that small maintenance habits prevent big frustrations. By caring for your machine, you’ll guarantee it weaves stitches effortlessly and lasts for years. Remember, a well-kept machine is the foundation of every perfect seam you create.