If your sewing machine keeps jamming, it might be due to improper threading, lint buildup, or tension issues. A dull or bent needle can also cause jams, along with low-quality thread. Regularly checking the bobbin and maintaining proper thread tension are essential steps. Cleaning the machine and lubricating its parts will help prevent future jamming. If the problem persists despite these efforts, there are additional troubleshooting tips that can guide you further.

Key Takeaways

- Improper threading can cause tangles, leading to jamming; always ensure correct threading of both upper and bobbin threads.

- Dull or bent needles create skipped stitches and blockages, so regularly inspect and replace needles as needed.

- Accumulated lint and debris can obstruct moving parts; routine cleaning of the bobbin area and needle plate is essential.

- Incorrect thread tension settings can contribute to jamming; regularly check and adjust to maintain even stitches.

- Persistent jamming may indicate deeper mechanical issues, and consulting a professional is advisable if troubleshooting fails.

Understanding the Mechanics of Sewing Machines

When you understand how a sewing machine works, it’s easier to troubleshoot issues like jamming. The sewing machine operates primarily through the needle, which moves up and down to create stitches. These stitches interlock with the thread from the bobbin, forming a secure seam. Familiarity with the basic mechanisms also allows you to take full advantage of advanced sewing machine features, such as automated threading and programmable stitch patterns. These capabilities can enhance your sewing experience, making it more efficient and enjoyable. Understanding the fundamentals ensures that you can easily adapt to using these advanced options without encountering common pitfalls.

Proper tension is essential, and the bobbin case must be correctly threaded to avoid problems. Feed dogs, the small components that move your fabric, can also cause jams if they're blocked or malfunctioning.

Regular maintenance, including cleaning and lubricating moving parts, keeps your machine running smoothly. If the handwheel feels stiff, it might indicate an internal issue.

Common Causes of Sewing Machine Jamming

Sewing machine jamming can be frustrating, especially when it disrupts your creative flow. Several common causes contribute to these pesky jams. Below is a table highlighting these issues:

| Cause | Effect | Solution |

|---|---|---|

| Improper Threading | Tangles and blockages | Verify upper and lower threads are correctly positioned. |

| Dull or Bent Needle | Skipped stitches and potential jams | Replace needles regularly. |

| Lint and Debris | Blocked components | Clean your machine often. |

Incorrect thread tension and low-quality threads can also lead to jamming. Remember to perform regular maintenance and check for any blockages to keep your sewing machine running smoothly.

Importance of Proper Thread Tension

Proper thread tension is essential for achieving even stitches and preventing jams in your sewing machine.

If the tension is off, you could face issues like thread bunching or breaking, especially when working with different fabrics.

Effects of Tension Imbalance

If you don't maintain the right thread tension, your sewing machine could jam, leading to frustrating interruptions in your project. Tension imbalance from improper thread tension can cause significant sewing machine jamming, resulting in uneven stitches and tangled threads. The upper thread may break, and the lower threads might not feed correctly.

| Issue | Cause | Effect |

|---|---|---|

| Sewing machine jamming | Improper thread tension | Projects are delayed |

| Uneven stitches | Tension imbalance | Fabric looks unprofessional |

| Broken upper thread | Incorrect thread tension | Extra time spent fixing |

| Poor feeding of fabric | Misaligned tension settings | Frustration while sewing |

| Untidy fabric loops | Poor maintenance | Decreased sewing enjoyment |

Regularly check thread tension settings based on your project needs and clean the machine to prevent jams.

Adjusting Tension for Fabrics

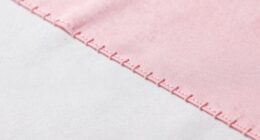

Maintaining the right thread tension is key to a smooth sewing experience, especially when working with different fabrics. Proper thread tension guarantees that the upper and lower threads interlock correctly, preventing fabric bunching and thread breakage.

When adjusting tension settings, keep in mind that lightweight fabrics typically need less tension, while heavier materials require increased tension for best stitch quality. If you notice jamming issues or uneven feeding, inspecting and adjusting the thread tension is essential.

Start with the manufacturer's suggested mid-point and fine-tune from there. Regular maintenance, including checking your tension settings, helps maintain consistent stitching and reduces the likelihood of problems, guaranteeing your sewing experience remains enjoyable and frustration-free.

Diagnosing Tension Issues

When your sewing machine starts jamming, one of the first things to contemplate is the tension of your threads. Proper thread tension is vital for balanced stitches; uneven tension can cause the upper thread and lower thread to pull improperly, leading to jamming.

If the upper thread tension is too tight, the fabric may get stuck, while loose tension can create loops and tangles. To maintain ideal stitch quality, adjust the tension dial and fine-tune it based on your fabric and thread type.

Regular cleaning of lint around the tension discs and consistent re-threading according to the manufacturer's instructions are essential for machine maintenance. These steps will help prevent future jamming issues and keep your sewing running smoothly.

Troubleshooting Jamming Issues

While sewing can be a relaxing hobby, dealing with a jamming machine can quickly turn it into a frustrating experience. To tackle troubleshooting jamming issues, start by inspecting the bobbin case and needle plate for lint and debris. Verify you've re-threaded both the upper thread and bobbin thread correctly, addressing any uneven tension. Check the needle for bends or dullness, as a bent or dull needle could cause jams. Regularly clean and maintain your machine by oiling moving parts and listening for unusual sounds that may indicate mechanical issues.

| Issue | Solution | Maintenance Tip |

|---|---|---|

| Lint and debris | Clean bobbin case and needle plate | Regular cleaning |

| Bent or dull needle | Replace with a new needle | Check needle regularly |

| Uneven tension | Re-thread and adjust tension | Regular maintenance |

| Unusual sounds | Inspect for mechanical issues | Listen while sewing |

| Jamming persists | Consult a professional | Schedule servicing |

Inspecting the Bobbin and Needle

To keep your sewing machine running smoothly, regularly inspecting the bobbin and needle is essential.

Start by checking the bobbin for even winding; an overfilled bobbin can cause uneven tension, leading to jamming. Make sure the bobbin type and size are compatible with your machine's specifications to avoid compatibility issues.

After removing the bobbin, clean the bobbin case with a soft brush or compressed air to eliminate lint and debris.

Next, confirm that the needle is securely inserted and not misaligned, as this can obstruct movement and cause jamming.

Finally, inspect the needle for any bends or damage; a dull or damaged needle can lead to skipped stitches and fabric pulling, further contributing to potential jamming issues.

Maintenance Practices to Prevent Jamming

To keep your sewing machine running smoothly and prevent jamming, establish a regular cleaning schedule to remove lint and debris.

Don't forget to lubricate it properly and replace the needle frequently, as these simple maintenance practices can make a big difference.

Regular Cleaning Schedule

Maintaining a regular cleaning schedule for your sewing machine is crucial, as it helps prevent jamming and keeps your projects running smoothly.

By incorporating consistent maintenance practices, you can tackle jamming issues before they start.

- Clean the bobbin area and feed dogs after every few projects to remove debris and lint.

- Establish a weekly maintenance routine to check thread tension and wipe down the exterior.

- Schedule a deep cleaning every 3 to 6 months to confirm all parts are functioning and in prime working condition.

Proper Lubrication Techniques

Regular cleaning alone won't solve all jamming issues; proper lubrication is key for guaranteeing your sewing machine operates smoothly.

You should incorporate oiling into your maintenance routine to reduce friction between moving parts and prevent jams. Aim to lubricate your machine every 2 to 6 months, depending on how often you use it. Always refer to your machine's manual for specific lubrication points.

Use high-quality oil, ideally mineral-based, and avoid heavy oils or household lubricants that can leave residue. Before oiling, verify you clean the machine thoroughly to eliminate lint and debris.

Following a scheduled routine—daily for cleaning, weekly for inspections, and monthly for lubrication—will keep your machine running efficiently and extend its lifespan.

Needle Replacement Frequency

Replacing your needle frequently is essential for preventing jamming issues in your sewing machine. It's recommended to swap out your needle after every project or every 6-8 hours of sewing. This practice guarantees that you avoid problems caused by dull or bent needles, which can lead to skipped stitches and jamming.

Keep these tips in mind:

- Always use the correct needle type and size for your fabric.

- Inspect your needle regularly for bends or wear.

- Confirm proper needle insertion to avoid misalignment.

Incorporating a routine needle replacement schedule into your sewing machine maintenance can enhance your sewing performance and stitch quality, greatly reducing the likelihood of jamming.

When to Seek Professional Help

When your sewing machine continues to jam despite your best troubleshooting efforts, it's time to contemplate seeking professional help.

If you've addressed common issues like thread jams, needle problems, and tension adjustments without success, there may be a deeper mechanical failure at play. Pay attention if the handwheel remains stuck after thorough cleaning; this signals potential internal component issues.

Repeated jamming, even with proper maintenance, could indicate mechanical damage requiring expert servicing. Additionally, if you notice unusual sounds during operation, don't ignore them—they often hint at underlying problems.

Finally, if your attempts at disassembly haven't resolved the issue, a qualified technician can provide the diagnosis and repair necessary to get your machine running smoothly again.

Resources for Sewing Enthusiasts

After evaluating whether to seek professional help for your sewing machine issues, it's important to explore the various resources available to enhance your sewing journey.

Consider these valuable options:

- Sewing machines manual and user manuals: Essential for setup, troubleshooting, and maintenance guides.

- Online platforms like JustAnswer: Connect with verified experts for real-time advice on common sewing problems.

- Local sewing groups and online forums: Engage with fellow sewing enthusiasts, share experiences, and attend workshops to improve your skills.

Utilizing these resources can greatly improve your project outcomes and overall sewing experience.

Whether you're a beginner or seasoned sewer, tapping into these knowledgeable communities and materials will provide the support you need to tackle any sewing machine challenges.

Frequently Asked Questions

How to Fix a Sewing Machine That Keeps Jamming?

To fix a sewing machine that keeps jamming, start by re-threading both the upper thread and bobbin, ensuring proper seating in the tension discs.

Check the needle for damage; replace it if it's dull or bent.

Clean the machine regularly, especially the bobbin case and feed dogs.

Adjust the thread tension to suit your fabric, and if problems persist, consider getting professional help to address any deeper issues.

Why Does My Sewing Machine Keep Getting Tangled Underneath?

Your sewing machine's turning into a tangled mess, isn't it? It feels like a fabric monster is wreaking havoc!

This chaos usually happens when you've threaded it incorrectly or the bobbin's overstuffed. Lint and debris might be partying in the bobbin case, blocking the threads.

Plus, if you're using cheap thread, it can shred and knot like it's auditioning for a disaster movie.

Keep it clean and use quality materials to restore peace!

Why Does My Sewing Machine Keep Getting Clogged?

If your sewing machine keeps getting clogged, it's likely due to lint, dust, or debris buildup in the bobbin case and needle plate.

You should clean these areas regularly to prevent obstruction. Using low-quality threads can also contribute to excess lint, so opt for good-quality options.

Additionally, check that you're threading your machine correctly and that the tension is set right.

Keeping up with maintenance will help minimize clogs and keep your machine running smoothly.

What Tension Should My Sewing Machine Be On?

Think of your sewing machine like a tightrope walker, balancing perfectly between threads.

For most fabrics, you'll want your tension dial set between 4 and 5. But if you're working with delicate materials, lower it to 2 or 3; for heavier fabrics, crank it up to 6 or 7.

Adjusting your tension settings regularly guarantees your stitches flow smoothly, just like that tightrope walker gliding effortlessly across the line.

Conclusion

In your sewing journey, don't let jamming jeopardize your joy. By understanding your machine's mechanics and maintaining proper tension, you can conquer common complications. Remember, regular maintenance is key to a smooth sewing experience. So, stay savvy and seek solutions before stress sets in. When you nurture your machine, it'll reward you with beautiful, seamless stitches. Embrace the art of sewing, and let creativity flourish without frustration! Happy stitching!