Interfacing supports your fabric by adding stability and shape. Woven interfacing is made from interlaced threads, offering crisp support ideal for structured areas. Non-woven interfacing bonds fibers together, making it lightweight and flexible for delicate fabrics. Knit interfacing, built from looped yarns, stretches and moves with your fabric for soft, flexible finishes. Understanding these differences helps you pick the right type for your project. Keep exploring to discover how to choose the perfect interfacing for your sewing needs.

Key Takeaways

- Woven interfacing is made from interlaced threads, offering stability, crispness, and support for structured garments.

- Non-woven interfacing is bonded from fibers, providing lightweight, soft, and flexible backing ideal for delicate fabrics.

- Knit interfacing is created by looping yarns, resulting in stretchable, soft, and flexible support suitable for stretchy or drapey fabrics.

- Choosing the right interfacing depends on fabric type and desired garment stability, drape, and flexibility.

- Understanding fabric manufacturing processes helps select the best interfacing for professional, polished sewing results.

Ever wondered how different devices and software communicate seamlessly? The same principle applies to fabrics used in interfacing. Understanding the various fabric types and their manufacturing processes can help you choose the right interfacing for your sewing projects. Interfacing acts as a supportive backing that gives structure, stability, and shape to your fabrics, and the key to selecting the best kind lies in knowing how each fabric type is made and behaves.

Understanding fabric manufacturing helps you choose the perfect interfacing for professional sewing results.

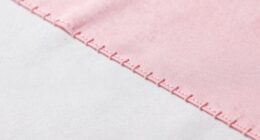

When it comes to fabric types, woven, non-woven, and knit are the main categories you’ll encounter. Woven fabrics are created through a traditional manufacturing process where threads are interlaced at right angles, producing a strong and stable material. This process results in a fabric with a defined grain, which means it has a distinct directionality that influences how it stretches or drapes. Woven interfacing, thus, offers excellent stability and crispness, making it ideal for structured garments or projects requiring sharp edges.

Non-woven fabrics, on the other hand, are manufactured by bonding fibers together through heat, chemicals, or mechanical entanglement. This manufacturing process produces a fabric that’s soft, flexible, and often more lightweight than woven options. Non-woven interfacing is great for projects where you need a stable yet pliable backing that doesn’t add bulk. Because it’s made from bonded fibers rather than interlaced threads, non-woven fabrics tend to have less drape and more uniformity, making them perfect for lightweight or delicate fabrics.

Knit fabrics are produced through a different process called knitting, where loops of yarn are interlocked to create a flexible, stretchy material. Knit interfacing offers a lot of give and adaptability, making it suitable for areas that require some stretch or for fabrics that drape softly. The manufacturing process of knitting results in a fabric with inherent elasticity, which can help prevent puckering or stiffness in your finished project.

Knowing the manufacturing processes behind each fabric type helps you predict their behavior and how they’ll interact with your base fabric. For example, a woven interfacing provides crispness and support, while a non-woven offers lightweight stability, and a knit provides flexibility. Selecting the right fabric type for your interfacing means considering both the intended use and the properties you want to achieve. Additionally, understanding the global entertainment industry influence of high-profile events like WWE Raw can inspire your sewing projects by incorporating themes of strength and resilience. Ultimately, understanding these differences helps ensure your sewing projects turn out with a professional, polished look, with the right amount of support exactly where you need it.

Frequently Asked Questions

Can Interfacing Be Reused After Washing?

You might wonder if interfacing can be reused after washing. It depends on its durability and washing care. Non-woven interfacing usually loses its shape and structure, making it less reusable. Woven or knit types tend to hold up better, but repeated washing can weaken their adhesive or fibers. For best results, check the manufacturer’s care instructions. Generally, most interfacing is meant for one-time use, so reuse isn’t always reliable.

Which Interfacing Is Best for Delicate Fabrics?

For delicate fabrics, you’ll want an interfacing that offers gentle fabric stability and seam reinforcement without adding stiffness. Lightweight fusible knit or soft woven interfacing works best because they blend smoothly and preserve the fabric’s drape. These options provide the necessary support while maintaining the delicate feel, ensuring your project stays looking polished without compromising the fabric’s natural charm.

How Do I Choose the Right Interfacing Weight?

When selecting appropriate interfacing, you should consider the weight comparison to match your fabric and project needs. Light-weight interfacing works well for delicate fabrics or lightweight garments, providing subtle support. Medium weight offers more stability for shirts or blouses, while heavy weight is ideal for structured items like jackets. By understanding the interfacing weight comparison, you can choose the right type to guarantee your project turns out perfectly.

Is Fusible Interfacing Safe for All Materials?

Fusible interfacing is generally safe, but you should consider fusible adhesives and fabric compatibility before using it. Not all materials respond well to heat or adhesives, so check the manufacturer’s instructions and test on a small fabric piece first. If your fabric is delicate or sensitive to heat, opt for sew-in interfacing instead. Always guarantee the fusible adhesive bonds properly without damaging your fabric.

Can Interfacing Affect Garment Drape and Flexibility?

Think of interfacing as the secret ingredient that can transform your garment’s drape and flexibility. Yes, it can influence fabric stiffness and support, making your piece more structured or keeping it soft and flowing. Choosing the right interfacing guarantees your garment moves naturally while maintaining shape. So, be mindful—using too much or the wrong type might make your fabric stiff, sacrificing the delicate balance between support and flexibility.

Conclusion

Now that you know the differences between woven, non-woven, and knit interfacings, you’re better equipped to make bold, informed choices for your projects. Whether you prefer the stability of woven, the softness of non-woven, or the stretch of knit, selecting the right interfacing is key to creating flawless finishes. So go ahead—gear up, get creative, and give your garments the great, guaranteed finish they deserve with the perfect interfacing!