Decoding thread labels is key to mastering your sewing projects. You'll find essential details like thread type, weight, and fiber content that impact your final results. For instance, cotton's breathable nature suits quilting, while polyester offers durability for heavy-duty tasks. Matching thread weight to fabric guarantees neat stitches and avoids puckering. Knowing these basics can considerably elevate your crafting. Stick around to access more tips and tricks that can enhance your sewing expertise further!

Key Takeaways

- Understand thread weight: Lower numbers indicate thicker threads; match with fabric type for optimal results in your projects.

- Identify fiber content: Choose cotton for breathability, polyester for strength, and specialty threads for decorative uses to enhance your sewing.

- Check needle size recommendations on labels to ensure compatibility with your chosen thread for smooth stitching and to prevent breakage.

- Be aware of common threading mistakes: Incorrect tension or mismatched thread weight can lead to issues like puckering or uneven stitches.

- Keep a reference guide handy: Familiarize yourself with thread types and uses to make informed selections for your sewing projects.

Understanding Thread Labels: The Basics

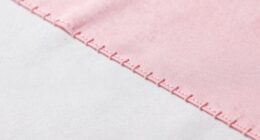

Thread labels are essential guides that help you choose the right materials for your sewing projects. They typically include key details like thread weight, type, and recommended uses, which are crucial in selecting the appropriate thread types for your needs.

Common thread types include cotton, polyester, and specialty threads, each with specific labels that indicate their composition and intended applications. The thread weight, marked by a number such as 40wt or 60wt, influences the thread's thickness and strength, affecting your project's appearance and durability.

Additionally, labels often suggest the compatible needle size and stitching techniques, ensuring you achieve the best results with various fabrics and sewing machines. Understanding these basics empowers you to sew with confidence. By familiarizing yourself with these recommendations, you can select the right tools and methods tailored to your projects. This knowledge not only enhances your sewing skills but also helps integrate crafting into your life seamlessly, allowing for a satisfying sewing and daily routine balance. As you master these techniques, you’ll find that your creativity flourishes, making sewing an enjoyable and fulfilling part of your day-to-day activities.

Types of Threads and Their Uses

Choosing the right type of thread can greatly impact your sewing projects. Here's a quick guide to help you choose the best thread for your needs:

| Thread Type | Best Uses | Key Features |

|---|---|---|

| Cotton | Quilting, general sewing | Natural finish, low stretch |

| Polyester | Sewing, embroidery | Versatile, strong, fade-resistant |

| Nylon | Heavy-duty applications | Elastic, durable |

| Specialty | Decorative projects | Unique finishes, specific handling required |

Cotton threads are perfect for quilting, while polyester threads offer strength for various projects. For heavy-duty tasks like upholstery, nylon is your go-to choice. Experiment with specialty threads to add flair to your creations!

Thread Weight: What You Need to Know

Understanding the types of threads is just the beginning; thread weight plays a significant role in your sewing projects too. The thickness of the thread impacts both the appearance and durability of your work.

Here are some key points to take into account:

- Common thread weights include 30, 40, and 50, with lower numbers indicating thicker threads.

- Heavier fabrics like denim typically need heavier thread weights, while lighter fabrics such as silk require finer threads.

- Using the right thread weight helps maintain stitch tension and prevents issues like puckering or weak seams.

Decoding Fiber Content in Thread

How can you guarantee you're selecting the right thread for your sewing project? Start by decoding the fiber content listed on the thread label.

Threads made of cotton are breathable and perfect for quilting or lightweight fabrics. If you need strength and durability, polyester threads are the way to go, especially for heavy-duty applications.

For decorative stitching, consider rayon threads; their sheen adds flair, but keep in mind they mightn't be as strong. Blended threads, combining cotton and polyester, offer versatility and improved performance for various tasks.

The Importance of Thread Length and Size

Understanding thread length and size is essential for achieving the best results in your sewing projects.

A thread that's too short can lead to constant re-threading, while one that's too long may cause tangling.

Understanding Thread Length Significance

Thread length plays an essential role in the success of your sewing projects, affecting both efficiency and quality. Choosing the right thread length guarantees you can sew without constant interruptions to change spools.

Here are some key points to take into account:

- Standard sewing threads typically range from 100 to 500 yards.

- Longer threads can lead to tension issues and uneven stitches if not managed well.

- Understanding thread length helps you budget and plan for materials effectively.

Impact of Size Variation

Choosing the right thread length isn't just about avoiding interruptions; it's also about recognizing how size variations can impact your projects.

The length of a screw determines how deep it penetrates materials, which directly affects its holding power and stability. Additionally, the screw size, indicated by diameter, plays an essential role in load-bearing capacity. Larger diameter screws can accommodate greater forces, making them important for demanding tasks.

Understanding the relationship between screw length and size is fundamental to prevent issues like stripping or shearing. By selecting the appropriate screw size and length, you guarantee structural integrity and safety in your projects, adhering to specifications that make all the difference in successful construction and assembly.

Selecting Appropriate Screw Length

Selecting the right screw length is essential for the success of your projects. The screw length, measured from the top of the head to the end of the shaft, guarantees a proper fit for your application.

Choosing the appropriate screw length affects:

- Holding power: A correctly sized screw secures materials effectively.

- Material integrity: Avoid damage by selecting screws that aren't too long or short.

- Structural reliability: Prevent potential failures by guaranteeing the right fit.

In American screw callouts, remember that screw length follows an "x" (e.g., #8 x 1.25). For flathead screws, measure from the top of the head, while other types may vary. Additionally, understanding the role of color accuracy in your project can enhance the overall quality of the finished product.

Choosing the Right Thread for Your Project

When you commence a sewing project, understanding the nuances of thread weight and type can make all the difference in your finished piece.

Lighter threads, like 50wt, are perfect for delicate fabrics, while heavier threads, such as 30wt, work best for quilting and upholstery.

Don't overlook thread types—cotton, polyester, or silk—all affect the feel and durability. Polyester is particularly strong and resistant to fading, making it a great choice for lasting projects.

Always match your thread to the fabric; for example, use cotton thread with cotton fabrics to avoid puckering.

Pay close attention to thread label details, including recommended needle size and tension settings, to guarantee your stitches look their best.

A thread weight chart can guide your choices effectively.

Common Threading Mistakes to Avoid

Even the most experienced sewists can fall prey to common threading mistakes that jeopardize their projects.

To guarantee a smooth sewing experience, make sure to avoid these pitfalls:

- Using the wrong thread weight: Always match the thread weight to the fabric type to prevent puckering or insufficient strength.

- Neglecting thread tension: Check and adjust tension settings based on the fabric and thread combination to avoid uneven stitches or breakage.

- Improper bobbin winding: A well-wound bobbin is vital; verify it's smooth and even to prevent thread jams.

Storage and Care Tips for Thread

To keep your threads in top shape, store them in a cool, dry spot with stable temperature and humidity levels.

Always handle them with clean hands or cotton gloves to protect the fibers.

Regular cleaning and inspections will help you maintain their quality and extend their lifespan.

Ideal Storage Conditions

Maintaining ideal storage conditions for your thread can greatly extend its lifespan and quality.

To keep your threads in top shape, follow these valuable tips:

- Store in a cool, dry environment between 65-70°F with 45-55% humidity to prevent deterioration.

- Keep threads away from direct sunlight to avoid fading and degradation.

- Use acid-free storage materials, like boxes or bags, to protect against damage from acids and moisture.

Proper Handling Techniques

Proper handling techniques are essential for preserving the quality and longevity of your thread.

Always store your spools in a cool, dry place, maintaining humidity levels between 45-55% and temperatures between 65-70°F. This prevents degradation and keeps your thread in top condition.

When handling threads, use clean, dry hands or cotton gloves to avoid transferring oils and dirt that can compromise thread quality.

For added protection, store each spool in acid-free materials, like boxes or bags, to shield them from light and dust damage.

If you need to clean your spools, use a soft brush and a mild soap solution, ensuring you avoid excessive moisture that could warp wood.

Cleaning and Maintenance Tips

Taking care of your thread spools goes beyond just handling them correctly; cleaning and maintenance play a key role in their longevity.

Here are some essential cleaning and maintenance tips for your wooden thread spools:

- Store spools in a cool, dry place with stable temperature and humidity (ideally 45-55% humidity and 65-70°F).

- Handle spools with clean, dry hands or cotton gloves to prevent oils and dirt from damaging the wood.

- Use acid-free materials for individual storage, protecting them from dust and environmental damage.

For cleaning, use a soft brush and mild soap solution, avoiding harsh chemicals.

If your spools need extensive repairs, seek professional help to maintain their historical and aesthetic value.

Protect your investment with these easy tips!

Exploring Specialty Threads and Their Applications

When you immerse yourself in the world of specialty threads, you'll discover that each type offers distinct advantages tailored to specific textile projects.

For instance, embroidery threads, often made from rayon or polyester, provide a beautiful sheen and durability perfect for decorative stitching on garments.

On the other hand, quilting threads are thicker and stronger, built to withstand the demands of machine quilting while minimizing breakage and fraying.

If you want to add shimmer, metallic threads can enhance your projects, but they require special handling to prevent tangling.

Understanding the weight and composition of specialty threads is essential, as lighter threads work well on delicate fabrics, while heavier threads are ideal for sturdier materials.

Enhancing Your Sewing Skills With the Right Thread

Choosing the right thread can elevate your sewing projects, as it directly influences the final outcome. Understanding the different thread types is essential for achieving the best results.

Here are key factors to take into account:

- Weight: Use a 40-weight thread for quilting to guarantee quality and durability.

- Fiber Content: Opt for cotton for breathability or polyester for strength, depending on your fabric.

- Thread Characteristics: Be aware of stretchability and sheen to match your thread with the fabric's properties.

Keeping a reference guide for thread weights and types handy will simplify your shopping process.

Familiarizing yourself with thread labels—like needle size recommendations—empowers you to make informed choices and enhances your overall sewing experience.

Happy sewing!

Frequently Asked Questions

How Do You Read Thread Labels?

To read thread labels, start by checking the thread weight, which tells you what needle and fabric to use.

Next, look for the type of thread—polyester, cotton, or nylon—as each has unique properties.

Pay attention to the recommended use for specific projects.

Also, note the tensile strength, which indicates how much force it can handle.

Finally, read the care instructions to guarantee your finished work remains durable and maintains its quality over time.

How to Read a Thread Callout?

Imagine you're on a treasure hunt, and the map's clues are thread callouts. To read one, start with the diameter, like "1/4," which tells you the screw's size.

Next, check the second number, such as "20," which indicates threads per inch. For metric screws, look for "M," followed by the diameter and pitch, like "M12 x 1.75," where 1.75 is the distance between threads.

This knowledge helps you find the right fit every time!

What Does #12 Mean on a Screw?

When you see a #12 on a screw, it refers to its size within the Unified Thread Standard. This designation means the screw has a major diameter of about 0.216 inches (5.49 mm).

Often, you'll find a second number indicating threads per inch, which affects how well it holds.

Larger screws like #12 are great for heavy-duty tasks, so understanding this size helps you choose the right fastener for your project.

What Do the Labels on Screws Mean?

When you look at screw labels, they indicate important details. The first number shows the screw's diameter, while the second number tells you the threads per inch, or thread pitch.

For metric screws, "M" denotes the diameter in millimeters. You'll also find abbreviations like UNC and UNF, which specify thread standards.

Understanding these labels helps you choose the right screw for your project, ensuring it meets safety and strength requirements.

Conclusion

Now that you've got the lowdown on thread labels, you're ready to tackle your next sewing project with confidence! Did you know that using the right thread can improve your sewing speed by up to 30%? By understanding thread types, weights, and materials, you'll not only enhance your skills but also create beautiful, durable pieces. So, grab your favorite threads, avoid common mistakes, and let your creativity shine! Happy sewing!