To fix looping or loose stitches, start by checking your machine’s tension settings—try tightening or loosening the upper thread tension gradually and test on scrap fabric. Re-thread your machine from scratch, ensuring the thread passes through all guides and tension discs correctly. Make sure your bobbin is wound evenly and inserted properly. Regularly clean lint from the bobbin case and tension parts. If you keep these steps in mind, you’ll improve stitch quality and discover helpful tips along the way.

Key Takeaways

- Re-thread the machine completely, ensuring all guides and tension discs are properly engaged.

- Adjust the upper thread tension gradually, testing on scrap fabric until stitches are even.

- Check and re-wind the bobbin to ensure even tension and correct placement in the bobbin case.

- Clean lint and debris from the bobbin area and tension discs regularly to prevent tension issues.

- Perform routine maintenance and test adjustments on scrap fabric before sewing your project.

Have you ever felt tension building up unexpectedly, making it hard to focus or stay calm? That’s a common frustration when your sewing machine starts producing looping or loose stitches. The culprit is often related to thread tension or bobbin issues. When these aren’t correctly adjusted or maintained, your machine struggles to produce even stitches, leaving you frustrated and ready to give up. Luckily, troubleshooting these problems isn’t complicated once you understand what to look for.

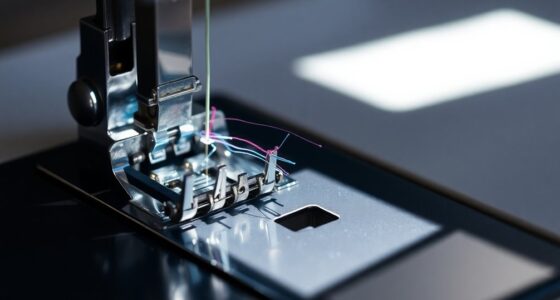

First, check the thread tension. If it’s too loose, your stitches won’t hold properly, resulting in loose or looping stitches on the fabric’s surface. Conversely, if the tension is too tight, your stitches might be puckered or the thread could break. To fix this, start by testing the tension on a scrap piece of fabric. Adjust the tension dial incrementally, making small changes and testing after each adjustment. Remember, every machine is different, so consult your manual for the recommended tension settings. When adjusting, ensure the upper thread tension is balanced with the bobbin tension; if either is off, you’ll face issues like looping or uneven stitches.

Check and adjust your thread tension for even, secure stitches.

Bobbin issues are often the next step to investigate. An improperly wound bobbin or one placed incorrectly in the bobbin case can cause tension irregularities. If the bobbin is wound unevenly or too tightly, it won’t feed smoothly, leading to loose stitches or loops. Remove the bobbin and re-wind it, making sure it’s evenly wound and not overfilled. Also, check that it’s correctly inserted in the bobbin case—incorrect placement can disrupt thread flow. When the bobbin case is dirty or lint-filled, the tension can be affected, so clean it carefully with a brush or compressed air. Sometimes, the bobbin tension itself may need adjustment, but only do this if your manual suggests it, as improper tension can cause more problems. Additionally, proper thread tension is essential for achieving high-quality stitches and avoiding tension-related issues.

Another common cause of tension issues is tangled or improperly threaded machine components. Re-thread the machine from the beginning, ensuring the thread passes through all tension discs, guides, and the needle correctly. Sometimes, a simple re-threading solves tension irregularities caused by misalignment or incomplete threading. Always use fresh, high-quality thread, and check for any knots or snags that might interfere with smooth feeding.

In essence, fixing tension issues revolves around confirming and balancing thread tension and ensuring the bobbin is wound and inserted correctly. Regular maintenance, such as cleaning lint and re-threading, can prevent most problems. When you take these steps, you’ll find that your stitches become even, secure, and your sewing experience much more enjoyable.

Frequently Asked Questions

How Do I Identify if My Machine’s Tension Discs Are Dirty?

You can tell if your machine’s tension discs are dirty by checking the thread tension. If your stitches are loose or looping, it might be due to lint or debris blocking the discs. To confirm, turn off your machine, remove the thread, and carefully open the tension area. Perform disc cleaning with a small brush or compressed air. Regular disc cleaning keeps tension smooth and prevents stitching issues.

Can Using Non-Standard Needles Cause Looping Issues?

Using non-standard needles is like trying to fit a square peg in a round hole—it can cause looping issues. Your machine’s needle compatibility is vital; incompatible needles can snag or skip stitches. Additionally, poor thread quality combined with the wrong needle exacerbates tension problems. Stick to recommended needles for your machine, and choose good quality thread, ensuring smooth sewing and preventing frustrating looping or loose stitches.

How Often Should I Replace My Machine’s Tension Spring?

You should replace your machine’s tension spring when it shows signs of wear, damage, or if tension issues persist despite proper adjustments. Regular tension spring maintenance helps prevent looping or loose stitches. It’s best to substitute tension components proactively, especially if you notice inconsistent stitch quality. Doing so ensures your machine runs smoothly, reduces tension-related problems, and keeps your sewing experience frustration-free. Always follow your machine’s manual for specific replacement intervals.

What Is the Impact of Using Different Thread Types on Tension?

Using different thread types impacts your machine’s tension because thread consistency and compatibility vary. Thicker or textured threads may cause tighter tension or loops if your machine isn’t adjusted properly, while thinner or slippery threads can lead to loose stitches. Always check that your thread matches your fabric and machine specifications, and use compatible threads to maintain balanced tension and prevent issues like looping or loose stitches.

Is There a Way to Test if My Tension Regulator Is Functioning Properly?

You can absolutely test if your tension regulator is working properly. Start by threading your machine with the fabric and thread you’ll use. Then, perform a tension test by sewing a straight line on scrap fabric, adjusting the tension dial as needed. If the stitches are even and balanced, your tension is fine. If they’re loose or tight, you might need to re-evaluate your thread tension and check your tension testing process.

Conclusion

Remember, mastering tension is like tending a delicate garden; with patience and care, your stitches will flourish. When loops or loose stitches appear, think of them as weeds trying to choke your progress. Tackle the issue step by step, adjusting your tension settings as needed. Soon, your machine will hum smoothly, and your fabric will dance in perfect harmony. Keep troubleshooting, and watch your sewing projects blossom into beautiful works of art.