Revealing the mystery of your sewing machine's shuttle hook is simpler than you think! This essential component connects the upper and bobbin threads, impacting stitch quality and performance. Misalignment or dirt can lead to skipped stitches and jams, so regular maintenance is key. Understanding the different types of shuttle hooks in vintage machines helps you make informed choices for your sewing projects. There's much more to explore about enhancing your machine's performance and stitch quality.

Key Takeaways

- Understand the shuttle hook's role in connecting upper and bobbin threads to create stitches effectively.

- Recognize the difference between vertical and horizontal shuttle hooks and their impact on fabric types.

- Regularly clean the shuttle hook to prevent dirt buildup, ensuring smooth thread management and consistent stitching.

- Check the timing and alignment between the needle and shuttle hook to enhance stitch quality and reduce jams.

- Consult your sewing machine manual for specific instructions on replacing or adjusting shuttle hooks for optimal performance.

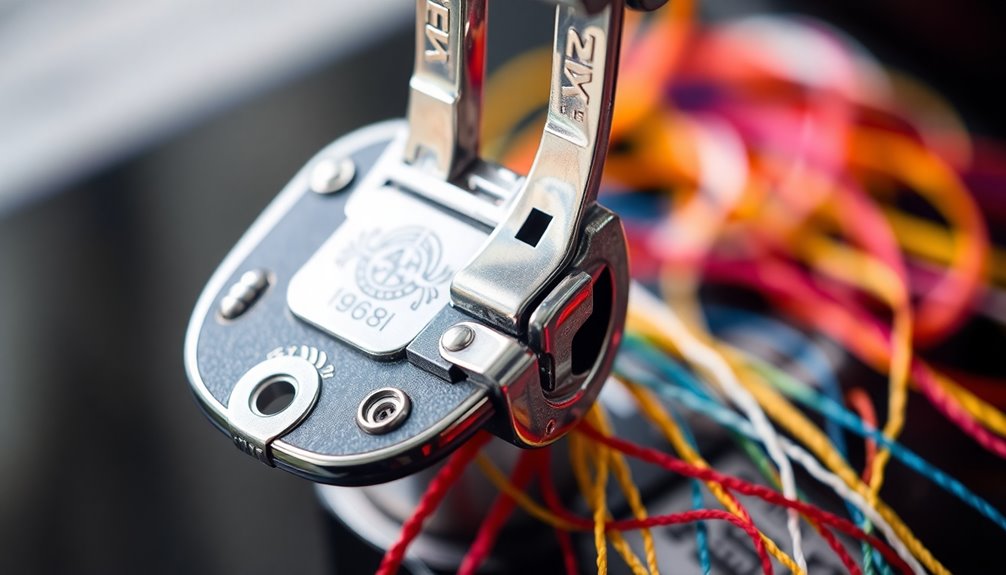

Understanding the Shuttle Hook Mechanism

Understanding the shuttle hook mechanism is vital for achieving smooth and consistent stitching in your sewing projects. This mechanism interfaces the upper thread with the bobbin thread, ensuring proper stitch formation.

If the timing between the shuttle hook and needle's misaligned, you might experience skipped stitches or thread jams. You should also note that shuttle hooks can be either vertical or horizontal, impacting the throw radius and overall sewing efficiency.

Regularly cleaning the shuttle hook area is important to prevent dirt buildup, which can hinder thread management. Additionally, the type of needle you use affects the shuttle hook's functionality; it must be correctly positioned and compatible with the hook for best thread interaction.

Types of Shuttle Hooks in Vintage Machines

When you explore vintage sewing machines, you'll notice a mix of vertical and horizontal shuttle hooks, each with its own quirks.

Understanding their compatibility with different models can really help you identify the best fit for your projects.

Plus, recognizing unique mechanisms will enhance your sewing experience and stitch quality.

Vertical vs. Horizontal Hooks

While both vertical and horizontal shuttle hooks play essential roles in vintage sewing machines, their distinct designs and mechanics greatly affect your sewing experience.

Vertical hooks, commonly found in machines like the Singer 15, oscillate up and down, while horizontal hooks rotate. This difference influences the timing and stitch quality of your projects.

It's crucial to acknowledge that tighter fitting vertical hooks work better with fine materials and thin threads, whereas looser fitting hooks are ideal for heavier fabrics.

Additionally, some vertical hooks can resemble rotary hooks in certain models, which may impact compatibility.

Compatibility With Vintage Models

Identifying the right shuttle hook for your vintage sewing machine is vital for maintaining ideal performance and stitch quality.

Vintage machines often feature unique shuttle hooks, like the flat round bobbin shuttle found in American BH-O models, which may not fit more common models. The design and curvature of these shuttle hooks considerably affect compatibility; for example, the difference between vertical and horizontal positioning can impact the shuttle's throw radius.

Compatibility issues often arise when swapping shuttle hooks due to variations in dimensions and mechanisms, leading to stitching problems. Understanding the specific type of shuttle hook in your machine, especially from manufacturers like Singer and Necchi, is essential for ensuring optimal performance and avoiding frustrating sewing mishaps.

Identifying Unique Mechanisms

Understanding the unique mechanisms of shuttle hooks in vintage sewing machines can greatly enhance your sewing experience.

Vintage machines often feature distinctive shuttle hooks, like flat round bobbins, which can differ markedly between brands. Some machines use vertical shuttle hooks, while others utilize horizontal designs; this variation affects thread management and the throw radius.

You'll also find unique curves and designs in shuttles from obscure American machines, setting them apart from more common models. Proper alignment and cleanliness of the shuttle hook are essential for effective thread pickup, as misalignment can lead to skipped stitches or binding issues.

Common Issues With Shuttle Hooks

When you're sewing, you might run into issues like binding and skipped stitches that can throw off your project.

These problems often stem from a misaligned shuttle or a clogged thread cutter, which can disrupt your thread management.

Regular maintenance is key to keeping your shuttle in top shape and ensuring smooth operation.

Binding and Skipped Stitches

Binding and skipped stitches can be frustrating, especially if the shuttle isn't properly aligned or obstructed. When the shuttle misaligns, it prevents the top thread from interacting correctly with the bottom thread, causing those annoying skipped stitches.

A dirty shuttle can also hinder your machine's performance, so regular cleaning is essential. Make sure the shuttle is positioned correctly and free from debris to help catch the thread loop during stitching.

Additionally, check your needle; a dull or improperly installed one can contribute to skipped stitches as well. Frequent inspection and maintenance of both the shuttle and needle can prevent these common issues, ensuring your sewing machine operates smoothly and delivers consistent stitching quality.

Thread Cutter Malfunctions

Skipped stitches can often lead to further complications, particularly with thread cutter malfunctions.

If your shuttle hook isn't clean or misaligned, the thread cutter might bind, resulting in uneven thread lengths that disrupt your sewing process. Regularly check the shuttle's setup and cleanliness to maintain its proper operation.

Also, verify the needle is straight and sharp; any issues here can directly affect both the shuttle hook and the thread cutter's performance.

Off-timing of the shuttle can further disrupt thread interaction with the cutter, so make timing checks part of your routine maintenance.

Importance of Timing and Alignment

Although you mightn't think about it often, the timing and alignment of your sewing machine's shuttle hook are vital for smooth operation.

Proper timing between the needle and shuttle hook is important; if they're misaligned, the hook may fail to catch the top thread, resulting in skipped stitches and inefficient operation.

Regular checks of the shuttle's alignment are necessary, as even slight misalignments can disrupt thread management and affect stitch quality.

A well-timed shuttle guarantees the needle drop coincides with the hook's passage, which facilitates effective thread pickup and reduces thread jams.

Maintaining correct timing and alignment not only enhances stitch consistency but also extends your machine's lifespan by minimizing wear on its components.

Troubleshooting Shuttle Problems

Maintaining proper timing and alignment is just the beginning when it comes to guaranteeing your sewing machine operates smoothly. Shuttle issues often arise from misalignment, leading to threading problems and skipped stitches.

Regularly inspect your shuttle to confirm it's clean and free of debris, as a dirty shuttle can cause thread jams. If you notice the timing is off, take the time to adjust it, as this is essential for the shuttle to catch the top thread effectively.

Also, make certain you're using a straight, sharp needle; its condition directly affects the shuttle's performance. By checking for binding and guaranteeing smooth operation, you can prevent unexpected machine shutdowns and keep your projects on track.

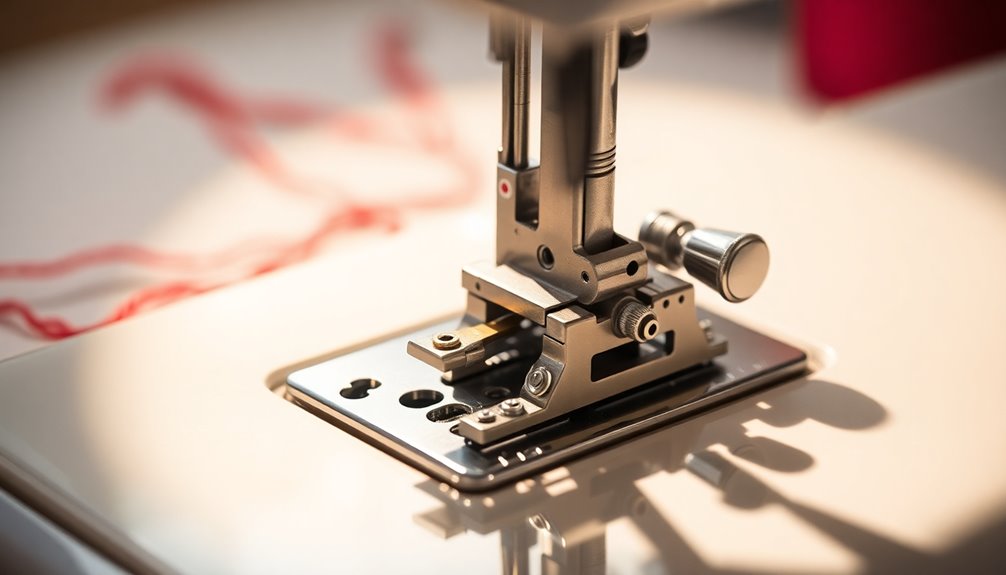

How to Maintain Your Shuttle Hook

To keep your sewing machine running smoothly, it's vital to maintain your shuttle hook regularly. Start by cleaning the shuttle hook to prevent dirt buildup, which can hinder thread management. Confirm your shuttle is properly aligned to avoid threading issues. Check your needle's condition; a straight and sharp needle is essential for peak shuttle performance. Additionally, maintain the timing between the hook and needle to prevent skipped stitches. Finally, inspect and adjust the clearance between the shuttle and hook according to your machine's manual.

| Maintenance Task | Frequency |

|---|---|

| Clean shuttle hook | After every project |

| Check needle condition | Before each use |

| Align shuttle | Monthly |

| Adjust timing | Monthly |

| Inspect clearance | Quarterly |

Recognizing Signs of Wear and Tear

Recognizing signs of wear and tear on your sewing machine's shuttle hook is essential for ensuring smooth operation.

Start by inspecting the shuttle for visible damage, like scratches or grooves, which can affect thread management and lead to skipped stitches.

Listen for unusual noises while you sew; louder sounds may signal a misaligned or damaged shuttle.

Check that the shuttle fits properly in your machine—too loose or too tight can cause binding or inconsistent stitching.

Regularly clean the shuttle area to prevent dirt buildup, as a dirty shuttle hinders thread transfer.

Finally, monitor the functionality of the thread cutter; wear in this mechanism can disrupt your sewing process with uneven thread cuts.

Replacing and Upgrading Shuttle Hooks

When you're replacing or upgrading shuttle hooks, it's essential to identify compatible options that match your machine's specifications.

Make sure to measure the gap between the hook butt and driver end for ideal stitch quality.

Once you've got the right hook, you'll want to install and adjust it properly to keep your sewing running smoothly.

Identifying Compatible Shuttle Hooks

How can you certify your sewing machine runs smoothly with the right shuttle hook? Start by identifying the correct shuttle hook that matches the shape and size compatible with your machine model.

Variations exist among manufacturers, so precise measurements are essential. Pay attention to the gap between the hook butt and the driver end, as this can affect compatibility with different thread types and needle sizes.

When replacing a shuttle hook, make sure it fits snugly; tighter hooks work well for fine materials, while looser hooks suit heavier fabrics.

Check for visible markings that correlate with known models, and consult your machine's manual or online resources to confirm compatibility.

Incorrect replacements can cause performance issues like thread jams and inconsistent stitching.

Installation and Adjustment Tips

After you've identified the right shuttle hook for your sewing machine, the next step is installation and adjustment. Confirm the new hook fits snugly in the bobbin case to maintain proper tension and stitch quality, especially with fine materials and thin threads.

Check the clearance between the hook butt and the driver end, aiming for a gap of 10-14 thousandths of an inch for ideal performance. Be cautious with timing adjustments; improper timing can cause thread jams.

Regularly clean the shuttle area to prevent dirt buildup that could interfere with operation. Finally, consult your machine's manual for any unique installation requirements to avoid compatibility issues. This way, you'll confirm smooth operation after installation.

Enhancing Stitch Quality Through Hook Adjustment

To enhance your sewing machine's stitch quality, adjusting the hook is essential. The gap between the hook butt and the driver end plays a significant role in maintaining proper timing and compatibility with various thread types.

Here are three key adjustments to take into account:

- Fit of the Hook: Use tighter fitting hooks for fine materials and looser hooks for heavier fabrics to maintain balanced stitch quality.

- Alignment Check: Regularly check your hook assembly's alignment; misalignment can lead to skipped stitches.

- Maintenance: Clean and lubricate the hook regularly to improve performance and consistency in stitch quality.

Resources for Vintage Sewing Machine Owners

While maneuvering the world of vintage sewing machines, it's important to tap into resources that cater specifically to your model's needs. Start by locating original manuals or service guides; these often provide essential details about your shuttle hook's design, maintenance, and timing specifications.

Regular maintenance, including thorough cleaning of the shuttle, will help prevent thread jams and guarantee consistent stitch quality. Engage with online forums and communities dedicated to vintage machines; fellow enthusiasts can offer invaluable insights, troubleshooting tips, and shared experiences.

Understanding the unique mechanisms of your vintage model is crucial, as improper timing and alignment of the shuttle can lead to skipped stitches. Utilize these resources to keep your sewing machine performing at its best!

Frequently Asked Questions

Why Is My Sewing Machine Not Picking Thread From the Shuttle?

If your sewing machine isn't picking up the thread from the shuttle, it could be due to several factors.

First, check if the needle's properly aligned and the right type for your machine.

Verify the shuttle's timed correctly, and that there's no dirt blocking it.

Also, confirm that the upper thread's threaded properly.

Misalignment of the shuttle can cause issues too, so double-check its positioning to resolve the problem.

How Do I Unlock the Sewing Machine?

To release your sewing machine, start by turning it off to avoid any accidents.

Next, check for any thread jams or debris around the shuttle area and remove them.

Inspect the shuttle's alignment—make sure it's properly seated in its race.

Look for any signs of damage or wear on the shuttle and hook mechanism.

If needed, consult your machine's manual for model-specific instructions to help you through the releasing process.

What Is the Shuttle Hook on a Sewing Machine?

A stitch in time saves nine, and understanding your sewing machine's shuttle hook can save you from frustration.

The shuttle hook's the part that works with the needle to catch the upper thread and loop it around the lower thread in the bobbin. Proper alignment and maintenance are key; if it's misaligned, you'll face skipped stitches.

Keep it clean, and you'll enjoy smooth, high-quality stitching every time you sew.

Why Is My Sewing Machine Locked?

If your sewing machine's locked, it might be due to a timing issue where the hook and needle aren't synchronized.

Check for thread jams caused by improper threading or tangled threads in the shuttle area. Misalignment of the shuttle could also hinder its interaction with the needle.

Regularly clean the shuttle area to avoid debris buildup, and make certain your needle is sharp and properly installed to prevent further locking issues.

Conclusion

Now that you've unraveled the secrets of your sewing machine's shuttle hook, it's time to put your newfound knowledge to the test. Will you notice an improvement in your stitching, or will hidden issues lurk beneath the surface? As you immerse yourself in troubleshooting and adjustments, remember: the right move could transform your sewing experience. So, what will you discover next? The journey into the world of vintage sewing machines is just beginning—are you ready for the challenge?