If your upper thread's getting caught on the shuttle hook, it's often due to improper threading, tension issues, or misalignment. You might also find burrs on the shuttle hook or neglected maintenance contributing to the problem. Ensuring the thread's correctly threaded, checking for rough patches, and adjusting tension can help prevent this hassle. Keeping your machine well-maintained is essential. Stick around for more tips and troubleshooting steps to keep your sewing running smoothly.

Key Takeaways

- Incorrect threading of the upper thread can cause it to catch on the shuttle hook during operation.

- Improper tension settings may lead to loose or tight upper thread, resulting in tangling.

- Misalignment of the bobbin or bobbin case can obstruct smooth movement, causing catches.

- Burrs or rough spots on the shuttle hook can snag the upper thread, creating issues.

- Lack of regular maintenance can lead to lint buildup, contributing to thread tangling.

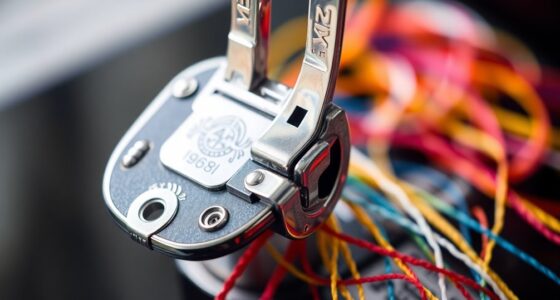

Function of the Shuttle in a Sewing Machine

The shuttle in a sewing machine plays an essential role in creating stitches by holding the bobbin, which contains the lower thread. As the needle moves up and down, the shuttle works in sync, usually moving back and forth or side to side under the needle plate. The shuttle picks up the lower thread, looping it around the upper thread supplied by the needle to form a secure stitch. Understanding how to operate a sewing machine effectively involves knowing how the shuttle interacts with the needle and thread, as this coordination is vital for achieving consistent stitch quality. Proper maintenance of the shuttle is also crucial, as any dirt or lint build-up can disrupt its functionality and lead to stitching issues.

This coordinated timing allows the upper thread to interlock with the lower thread, forming a strong stitch. The shuttle's design, often resembling a boat or cylinder, guarantees smooth movement, which is critical for maintaining stitch quality.

Regular cleaning and lubrication of the shuttle mechanism help prevent lint buildup, allowing peak performance. Proper alignment of the shuttle with the needle is fundamental to avoid issues like thread tangling or skipping stitches.

Common Causes for Thread Catching on the Shuttle Hook

When your upper thread catches on the shuttle hook, it can disrupt your sewing project and lead to frustration. One common cause is incorrect threading of the upper thread, which may require re-threading to fix.

Additionally, improper tension can make the upper thread too loose or too tight, resulting in thread tangling with the shuttle hook. Misalignment of the bobbin or bobbin case can also prevent the upper thread from being picked up correctly, causing further issues.

Inspecting for a burr or rough patch on the shuttle hook is essential, as these can snag the upper thread. Regular maintenance, including cleaning the shuttle area, guarantees smooth operation and helps prevent these frustrating catches.

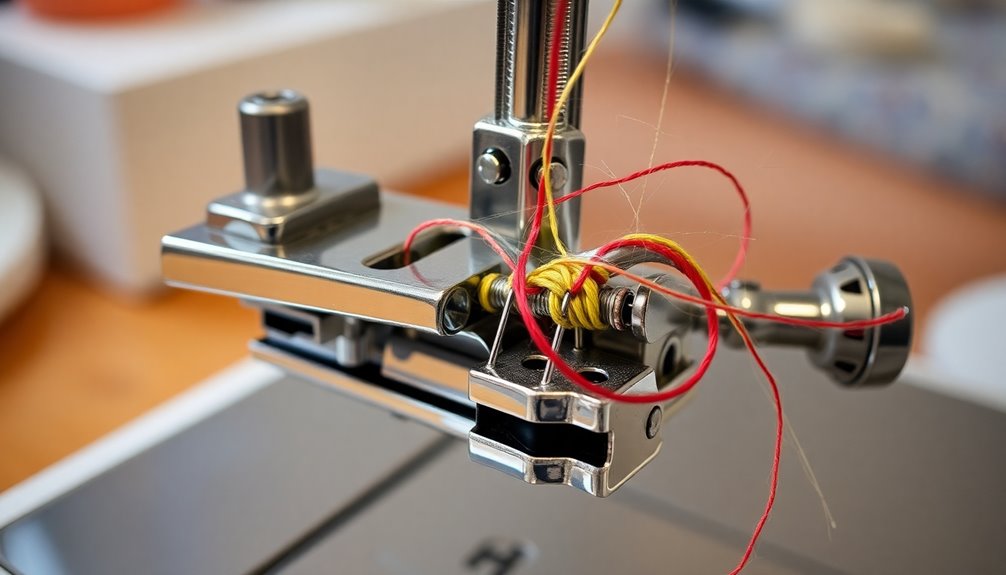

Troubleshooting Steps for Shuttle Issues

If you're facing issues with your shuttle hook, it's important to follow a systematic approach to troubleshoot effectively. Here are some steps to guide you:

- Check Threading: Verify the upper thread is threaded correctly through all guides and tension disks. Improper threading can lead to tangling on the shuttle hook.

- Inspect for Burrs: Regularly examine the shuttle hook and surrounding areas for burrs or rough spots. Use a fine emery board to smooth any irregularities.

- Examine the Needle: Confirm that the needle is properly inserted and not bent, as this can misalign the thread path.

- Adjust Tension: Modify the upper thread tension based on your fabric type, since incorrect tension can contribute to threading issues.

Importance of Regular Maintenance

Maintaining your sewing machine is just as important as troubleshooting any issues that arise. Regular maintenance, including cleaning and lubricating the shuttle area, prevents lint buildup that could cause the upper thread to catch on the shuttle hook.

By inspecting and polishing rough patches or burrs on the shuttle, you guarantee smooth operation and reduce thread snags during sewing. Confirming that the shuttle and hook are correctly aligned helps maintain consistent stitch quality, preventing operational issues.

Following the manufacturer's maintenance schedule greatly extends your machine's life and minimizes threading problems. Additionally, regularly checking and replacing worn components like the needle and bobbin case can prevent complications that lead to the upper thread getting caught, guaranteeing a seamless sewing experience.

Tips for Proper Threading and Tension Adjustment

To achieve smooth and trouble-free sewing, proper threading and tension adjustment are essential. Follow these tips to prevent the upper thread from snagging on the shuttle hook:

- Check Threading: Verify the upper thread passes through all components, including the take-up lever, with the presser foot up.

- Adjust Tension: Modify the tension based on your fabric and thread type; incorrect tension can cause issues.

- Inspect Regularly: Look for burrs or rough patches around the shuttle hook to avoid snagging the upper thread.

- Use Quality Thread: Choose high-quality thread suitable for your machine and fabric; weak or old thread can lead to catching problems.

When to Seek Professional Help

If you've tried rethreading and adjusting the tension but the upper thread keeps catching on the shuttle hook, it's time to contemplate professional help.

Signs like frequent needle breaks or persistent thread nests indicate serious issues that can lead to further damage.

Regular servicing not only addresses these problems but also helps prolong your machine's lifespan.

Signs of Serious Issues

While sewing can be an enjoyable and rewarding experience, encountering persistent issues with your machine, such as the upper thread repeatedly getting caught on the shuttle hook, signals that it's time to seek professional help.

Look for these signs of serious issues:

- Thread nests and tangling persist even after adjusting the tension settings.

- A broken needle occurs frequently, hinting at possible misalignment or burrs.

- The shuttle doesn't move smoothly or emits unusual noises, suggesting internal damage.

- You regularly experience skipped stitches or difficulty picking up the bobbin thread, which may indicate a serious timing issue.

If you notice any of these symptoms, professional servicing is essential to keep your machine running smoothly.

Benefits of Professional Servicing

When your sewing machine starts acting up, seeking professional servicing can be a game changer. Experts can quickly identify timing issues causing the upper thread to snag on the shuttle hook, ensuring smooth operation.

They'll perform an expert inspection to remove any small burrs or rough patches that contribute to thread tangling, enhancing your stitching quality. Regular professional servicing not only addresses unnoticed wear and tear but also prolongs your sewing machine's lifespan.

Technicians provide essential adjustments and calibrations for ideal thread tension and alignment, preventing recurring frustrations like thread nests or broken needles.

When DIY troubleshooting fails, don't hesitate to seek professional help—it's a time-saver that keeps your sewing projects on track.

Frequently Asked Questions

Why Is My Top Thread Getting Stuck?

If your top thread's getting stuck, it could be due to a few common issues.

First, check if you've threaded the machine correctly; improper threading can cause problems.

Next, inspect your tension settings; if they're too tight, the thread might snag.

A bent needle or rough spots on the shuttle hook can also lead to snagging.

Regular maintenance, like cleaning and oiling, helps prevent these issues and keeps your sewing smooth.

Why Does My Sewing Machine Keep Jamming the Top Thread?

If your sewing machine keeps jamming the top thread, check a few key areas.

First, verify you've threaded the machine correctly; improper threading can cause jams.

Next, inspect the bobbin area for debris or lint that might obstruct the shuttle's movement.

Also, consider the quality of your thread—using old or low-quality thread can lead to issues.

Finally, regular maintenance and cleaning can help keep your machine running smoothly and prevent further jams.

Why Is My Top Thread Pulling?

Have you ever wondered why your top thread's pulling? It could be due to incorrect threading, which misguides the thread along the machine's path.

If your tension settings are off, that can also cause uneven pulling. A bent needle might misalign the thread, leading to issues too.

Plus, lint or debris in the bobbin area can hinder smooth operation. Regularly cleaning and maintaining your machine can help prevent these frustrating problems.

Why Does My Thread Keep Snagging?

If your thread keeps snagging, it might be due to a few common issues.

First, check your threading; it may not be following the correct path.

Then, examine the tension settings; if they're too tight or loose, that could be causing problems.

Also, inspect the shuttle hook for any rough spots or damage.

Finally, using old or low-quality thread can lead to fraying, increasing the chances of snagging.

Conclusion

In the intricate dance of sewing, when your upper thread catches on the shuttle hook, it's like a tangled thread in a beautifully woven tapestry. By troubleshooting and maintaining your machine, you guarantee smooth, harmonious stitching, allowing creativity to flow freely. Remember to adjust your threading and tension like a skilled conductor guiding an orchestra. And if the music falters, don't hesitate to seek professional help to restore the rhythm of your craft.